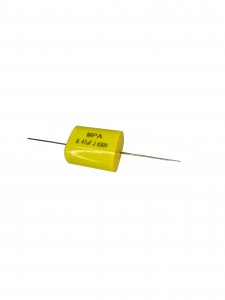

104J 630V Film Capacitor

Features

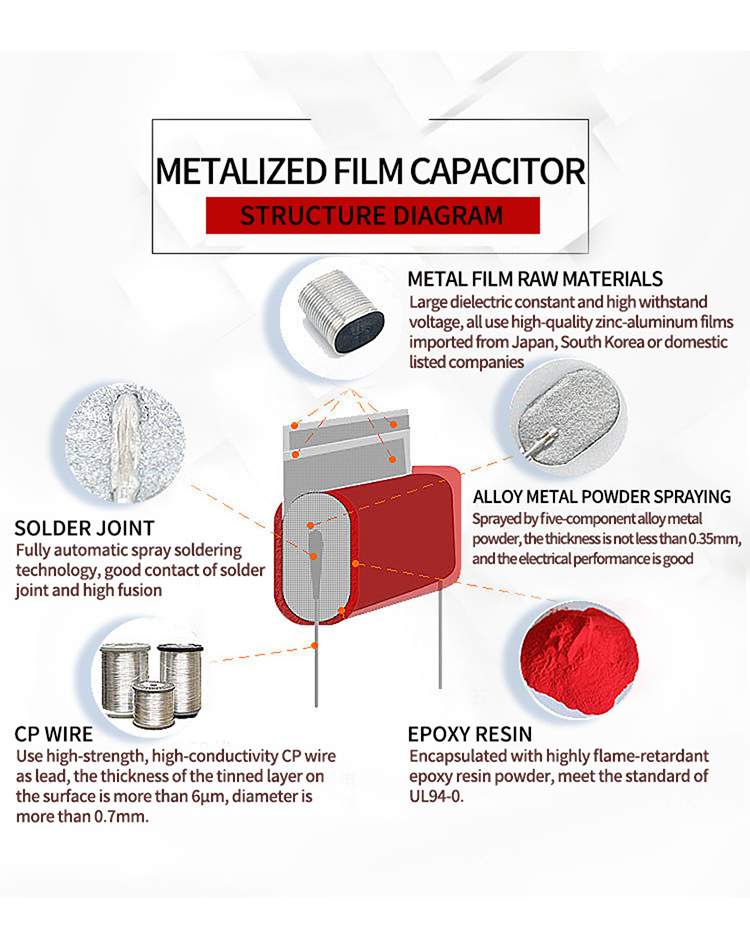

Metallized polypropylene film, non-inductive wound construction

Low loss at high frequency and low internal temperature rise

Good self-healing performance, high impact strength

Flame retardant epoxy resin coating

Structure

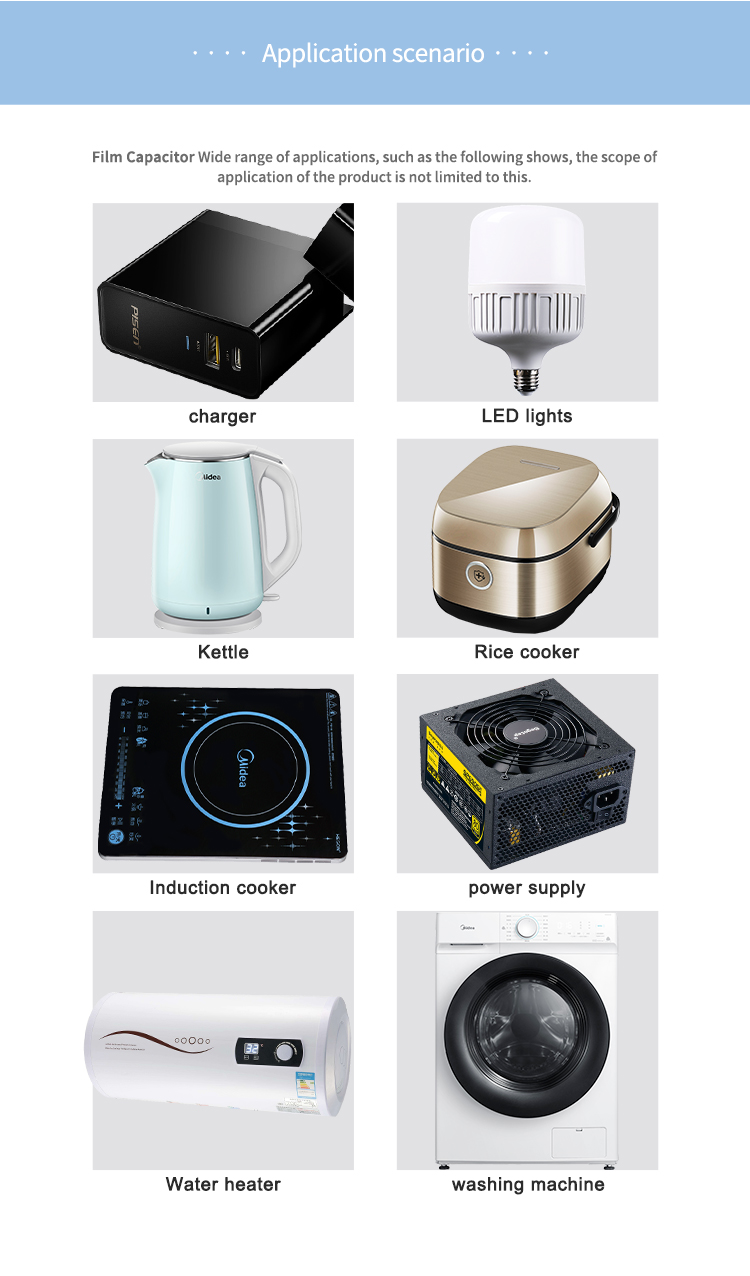

Application

Certification

FAQ

Why do new energy vehicles choose film capacitors?

The film capacitor on the main circuit of the car driver is used for energy storage and buffering. The driving motor needs to provide a large instantaneous current. Due to the large distributed inductance of the wire from the battery to the driver, and the discharge characteristics of the battery, the battery side cannot output such a large current instantly, so some film capacitors need to be added as a buffer (capacitor discharge is very fast), this film capacitor has another advantage, that is, the energy fed back by the motor can be stored when the car brakes (because the instantaneous feedback current is too large, the battery cannot absorb it in a short time). Some better new energy vehicles add a large-capacitance supercapacitor to the main circuit on the DC side of the driver to absorb the energy of braking feedback in order to improve energy utilization. However, the cost of supercapacitors is very high. At present, automobile manufacturers are temporarily replacing them with other solutions.