Mini box Metallized Polyester Film Capacitor MEB (CL23B)

|

Technical requirements reference Standard |

GB/T 7332 (IEC 60384-2) |

|

Climatic Category |

55/125/56 |

|

Operating Temperature |

-55℃~105℃(+85℃~+105℃: decreasing factor1.25% per℃ for UR) |

|

Rated Voltage |

63V,100V,250V |

|

Capacitance Range |

0.001μF~1μF |

|

Capacitance Tolerance |

±5%(J), ±10%(K) |

|

Withstand Voltage |

1.5UR , 5sec |

|

Insulation Resistance(IR) |

Cn≤0.33μF, IR≥15000MΩ; Cn>0.33μF, RCn≥5000s at 100V, 20℃, 1min |

|

Dissipation Factor (tgδ) |

1% Max , at 1KHz and 20℃ |

Application Scenario

Charger

LED lights

Kettle

Rice cooker

Induction cooker

Power supply

Sweeper

Washing machine

CL23B Application

It is widely used in filtering and low pulse circuits. It is suitable for DC blocking, bypassing and coupling of DC and VHF level signals.

Dongguan Zhixu Electronic Co., Ltd. (also JYH HSU(JEC)) was established in 1988. It is a new modern enterprise specializing in the production and sales of film capacitors, X/Y safety capacitors, varistors/thermistors, and medium, high and low voltage ceramic capacitors. It is a new modern enterprise dedicated to R&D, production and sales of electronic components.

Certifications

Certification

JEC factories have passed ISO9001 and ISO14001 management certification. JEC products strictly implement GB standards and IEC standards. JEC safety capacitors and varistors have passed multiple authoritative certifications including CQC, VDE, CUL, KC , ENEC and CB. JEC electronic components comply with ROHS, REACH\SVHC, halogen and other environmental protection directives, and meet the EU environmental protection requirements.

About Us

The founder of the company has been engaged in capacitor research and development and circuit design for more than 20 years. The company has implemented a new concept of nanny service in the industry, freely assisting customers in circuit research and development, capacitor customization selection, customer circuit optimization and upgrading, product application abnormal problem analysis, and provides our clients with a new model of unique and considerate services.

1. Is the thickness of the film in the film capacitor the thicker the better?

No, the thicker the dielectric (film), the higher the voltage it can withstand, and vice versa, the thinner the film, the lower the voltage it can withstand. Moreover, the capacitance of the film is related to the metal coating. The thicker the metal coating, the stronger the overcurrent capability, but the result is the greater the heat generation. On the contrary, the thinner the metal coating, the weaker the overcurrent capability, the lower the heat generation. When choosing film capacitors, one should not only consider the thickness of the capacitor. The film capacitor should be selected according to the actual needs and related criteria.

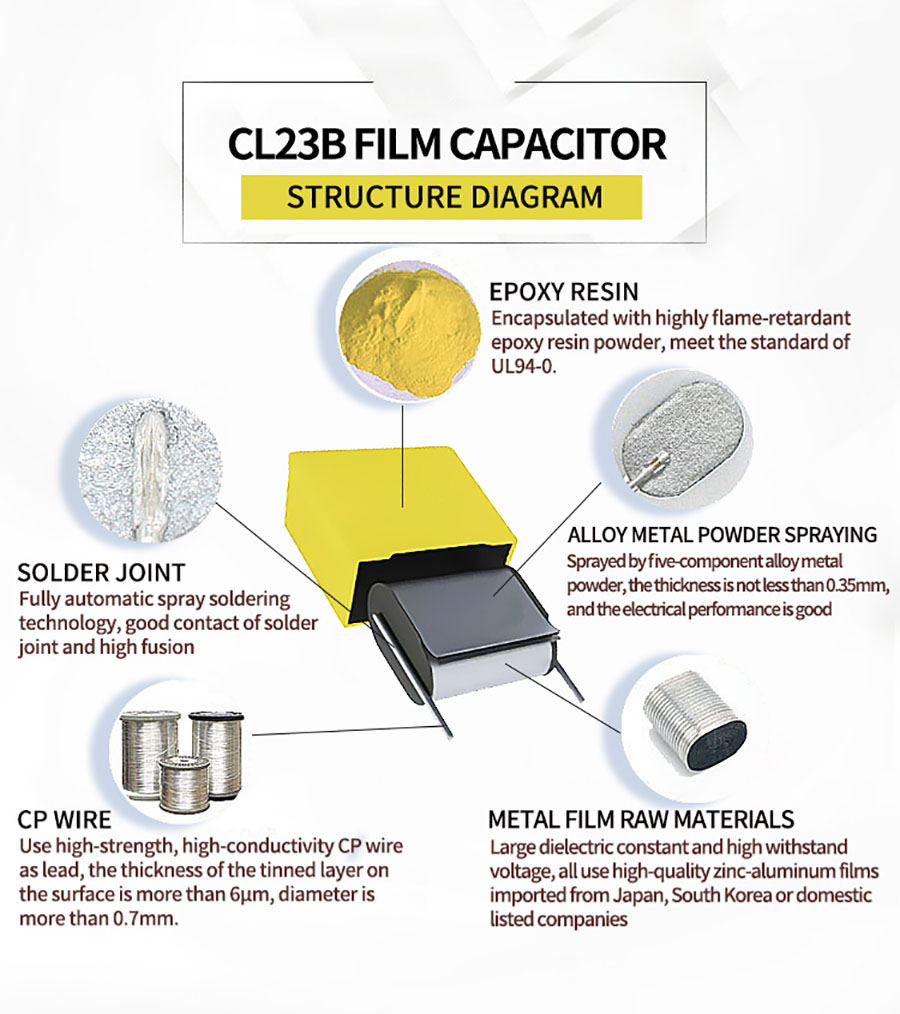

2. Why would the capacitance of film capacitor decrease?

The capacitance of the film capacitor depends on the area of the film metal layer, so the decrease in capacitance is mainly caused by the reduction of the area of the metal plating layer affected by external factors.

In the capacitor manufacturing process, there is a trace of air between the film layers, and when the capacitor is working, the metal coating of the metalized film of ozone is oxidized immediately after encountering the oxygen decomposed by ozone, and the transparent and non-conductive metal oxides ZnO and Al2O3 are generated. The actual manifestation is that the area of the plate is reduced, and the capacitance of the capacitor is reduced. Therefore, eliminating or reducing the air between the membrane layers can slow down the capacitance decay.