Thermistors play a crucial role as electronic circuit components, serving functions such as temperature compensation in instrument circuits and thermocouple cold junctions. Leveraging the NTC thermistor’s self-heating characteristic enables the implementation of automatic gain control and the creation of protection circuits for RC oscillator amplitude stabilization.

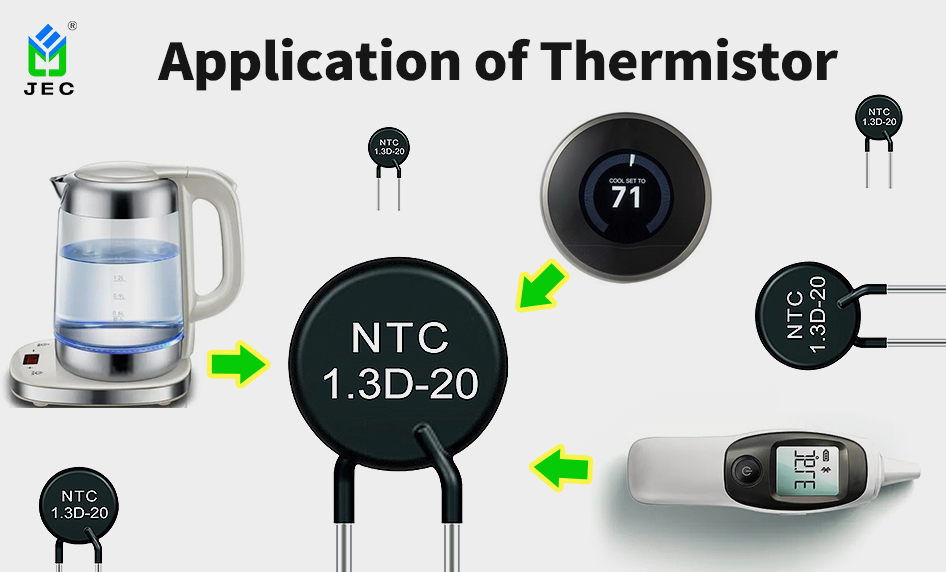

Primarily employed for overheat protection in electrical equipment, non-contact relays, constant temperature applications, automatic gain control, motor starting, time delay, automatic degaussing in color TVs, fire alarms, and temperature compensation, PTC thermistors offer versatile applications. Have you ever wondered about the underlying principles of thermistors in electric kettles?

The electric kettle’s thermistor operates on a straightforward principle. By passing current through the component, it heats up to a specific temperature. Once the temperature surpasses the designated threshold, the resistance increases, leading to a reduction in current or output. This mechanism effectively prevents the kettle from overflowing or drying out.

Beyond its role as a heating element, the thermistor can also function as a “switch,” commonly referred to as a “thermal switch.” As current flows through the component, heating occurs, causing the temperature of the heating element to rise. Upon reaching the Curie point, the resistance increases, limiting further current escalation. Consequently, reduced current leads to a drop in component temperature, causing a decrease in resistance and triggering a cycle of temperature control.

Thus, the thermistor serves the dual purpose of maintaining a specific temperature range and acting as a protective switch. Widely applied as a heating element in devices like heaters, electric soldering irons, drying cabinets, air conditioners, and more, it effectively safeguards electrical appliances from overheating.

We are JYH HSU (JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.), an electronic components manufacturer. Our factories hold ISO 9000 and ISO 14000 certifications. If you have technical inquiries or require samples, please feel free to contact us.

Post time: Dec-20-2023