Capacitors are one of the key components in maintaining the reliability of electronic devices and circuits. Here are some methods for preventing film capacitor failures:

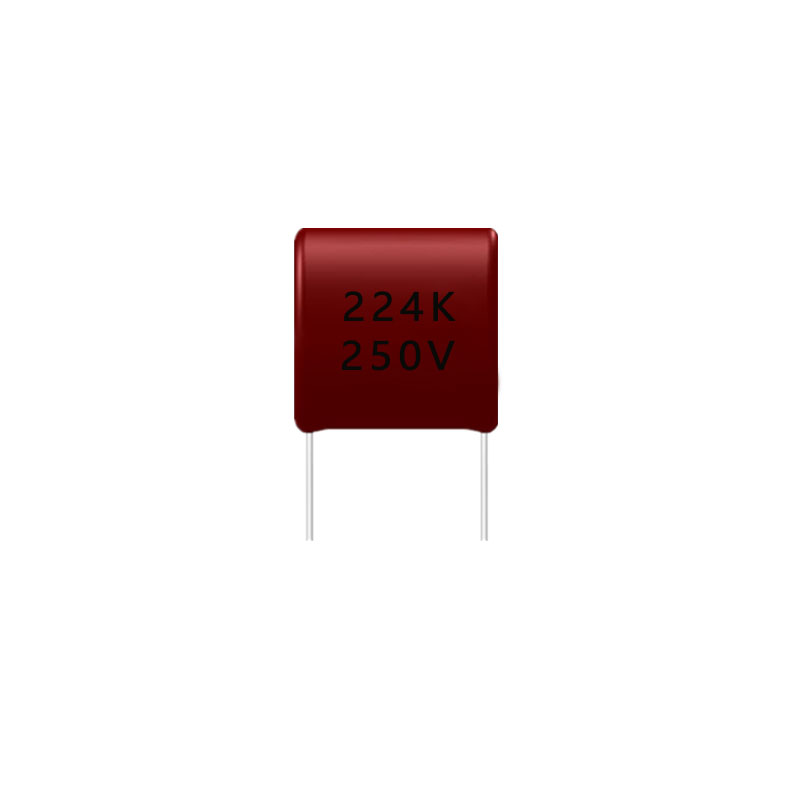

Properly select capacitors: Choosing the right type and parameters of capacitors for a specific application is crucial. Ensure that the rated voltage, capacitance value, temperature characteristics, and other specifications of the capacitor meet the design requirements. Excessive voltage or current can lead to capacitor damage.

Pay attention to voltage polarity: If capacitors have polarity, they must be connected correctly. Reverse polarity connection can lead to capacitor damage. Make sure that capacitor polarity is correctly identified in circuit design and installation.

Avoid overvoltage: Use overvoltage protection circuits such as TVS diodes or MOV (metal-oxide varistor) to prevent capacitors from experiencing excessive voltage. These protective devices can absorb voltage spikes and protect the capacitors from damage.

Control operating temperature: Ensure that capacitors operate within their rated temperature range. High temperatures can reduce capacitance values and shorten the capacitor’s lifespan. Low temperatures can also affect capacitor performance.

Prevent overcurrent: Use current limiters, fuses, or current-limiting circuits to prevent capacitors from experiencing excessive current. Excessive current can cause capacitors to heat up and become damaged.

Avoid mechanical damage: Capacitors are often fragile and can be easily damaged by mechanical shocks or vibrations. Consider mechanical protection in the design or use protective covers or mounting fixtures near the capacitors.

Quality control: Ensure the use of high-quality capacitors and avoid counterfeit products. Regularly inspect capacitors for cracks, leakage, or other obvious defects.

Maintenance and inspection: Regularly inspect and maintain electronic equipment, especially capacitors in aging or critical applications. Replace aging or problematic capacitors to ensure system reliability.

Use capacitors within their rated operating conditions: Avoid exceeding the capacitor’s rated operating conditions, including voltage, current, temperature, etc. Use capacitors according to the manufacturer’s recommendations.

Avoid open-circuit or short-circuit conditions: Do not operate capacitors in open-circuit (without a load) or short-circuit (directly connecting the positive and negative terminals), as this can damage the capacitors.

By implementing these measures, you can reduce the risk of film capacitor failures and improve the reliability and performance of electronic devices and circuits. Pay special attention to the use and conditions of capacitors in circuit design and maintenance to ensure their stable operation over an extended period.

This article is provided by JYH HSU Electronics, a manufacturer of electronic components such as capacitors and resistors.

Post time: Nov-03-2023