What is a film capacitor? A film capacitor is a type of capacitor made by sandwiching metal foil between layers of plastic film, such as polyester, polypropylene, polystyrene, or polycarbonate.

Due to its advantages such as non-polarity, high voltage resistance, good temperature characteristics, high insulation impedance, and good frequency response, film capacitors are widely used in industries such as communications, household appliances, and medical equipment, securing a place in the electronic device market.

While many people are familiar with film capacitors, they may not be aware that film capacitors can be further classified into wound film capacitors and stacked film capacitors.

Wound film capacitors and stacked film capacitors are distinguished by their internal construction.

Stacked film capacitors involve layering multiple polymer films and metal foils together to form the internal structure of the capacitor. This structure resembles stacking pages of a book, with each layer playing a crucial role.

The manufacturing process of stacked film capacitors is relatively complex, requiring precise control over the thickness, uniformity, and flatness of each film and metal foil layer.

Additionally, insulation material needs to be added between layers to prevent internal short circuits. These assembled capacitor cores are then encased in metal shells and secured with pins through welding or pressing.

Stacked film capacitors offer several advantages:

Higher capacitance density: Due to their multilayer structure, stacked film capacitors have higher capacitance density, enabling larger capacitance to be achieved within smaller volumes. This feature makes stacked film capacitors promising for miniaturized and lightweight electronic devices.

Better high-frequency characteristics: Stacked film capacitors exhibit excellent high-frequency characteristics. Due to insulation materials and structural designs between layers, the equivalent series inductance (ESL) and equivalent series resistance (ESR) of stacked film capacitors are relatively low, making them suitable for applications like filtering, coupling, and energy storage in high-frequency circuits.

Good voltage and current endurance: Furthermore, stacked film capacitors demonstrate good voltage and current endurance, maintaining stable performance even in harsh operating environments.

Stacked film capacitors, with these advantages, find wide applications in fields such as electronic devices, industrial control, and renewable energy.

Whether it’s stacked film capacitors or wound film capacitors, ensuring quality and reliability is crucial. Only film capacitors with excellent quality and reliability can guarantee the stable operation of electronic devices.

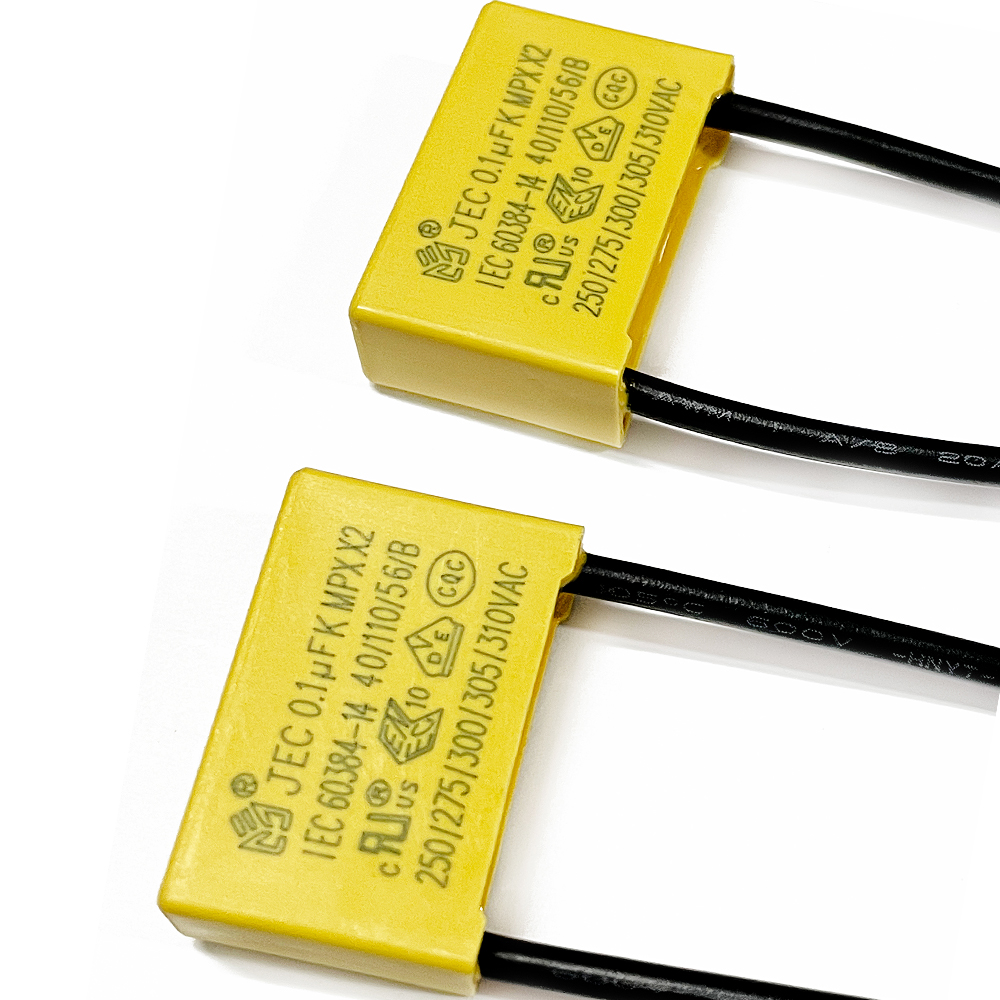

This article was provided by JYH HSU (JEC) Electronics Ltd (or Dongguan Zhixu Electronic Co., Ltd.), an electronic components manufacturer who produces all kinds of capacitors and resistors. JEC factories hold ISO 9000 and ISO 14000 certifications.

Post time: Apr-10-2024