Capacitors are essential components in electronic devices. As a fundamental element, film capacitors are widely used in industries like lighting and new energy vehicles because of their advantages: wide operating temperature range, strong self-healing ability, high voltage tolerance, non-polarity, and excellent frequency characteristics.

But with so many types and brands of film capacitors on the market, how do you pick the right and reliable one? You can focus on three main aspects: capacitance, rated voltage, and lead type.

1. Check the Capacitance

Capacitance is the core parameter of a film capacitor, measured in farads (F), commonly expressed in microfarads (μF) or nanofarads (nF).

When selecting, determine the capacitance range based on your actual application. Bigger isn’t always better—you need to balance the application requirements, cost, and size to avoid waste or underperformance.

For example, power supply filtering typically requires film capacitors in the range of 0.1μF to 100μF to remove high-frequency noise from circuits. Too high, and the large current may affect power startup and interfere with other components; too low, and the filtering won’t be effective, leaving residual noise.

2. Check the Rated Voltage

The rated voltage of a capacitor indicates the maximum DC voltage it can safely and stably handle over time.

When choosing a film capacitor, make sure the circuit’s operating voltage stays within 70–80% of the capacitor’s rated voltage. If startup surges or voltage fluctuations exceed the rated voltage, the capacitor may fail.

3. Check the Lead Type

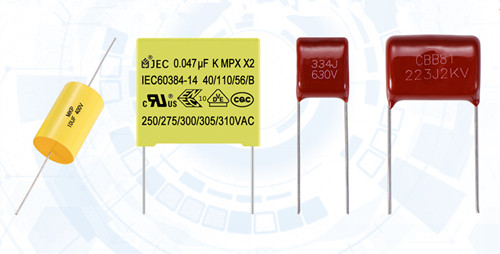

You also need to consider the lead type when selecting a film capacitor. The common lead types are radial and axial.

Radial leads: Both leads extend from the same end, allowing the capacitor to stand upright on the PCB. They are suitable for automated assembly and compact layouts.

Axial leads: Each lead extends from opposite ends, typically mounted lying flat on the PCB, with both ends fixed. Ideal for isolated wiring and reducing interference.

Which one to choose depends on your PCB design, available space, and potential signal interference. Picking the right lead type makes installation easier and ensures a more stable circuit.

This article is provided by JYH HSU (JEC) Electronics. JEC is a research, development, production, and sales-oriented company specializing in manufacturing and selling various electronic components such as capacitors and resistors.

Post time: Sep-09-2025