In the world of electronic components, a breakdown usually means disposal and replacement. However, film capacitors possess a unique “superpower”—self-healing. When a breakdown occurs in the circuit, they can repair themselves like a wound healing, and continue to function normally.

What are Film Capacitors?

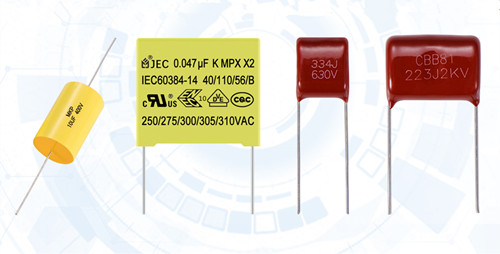

Film capacitors consist of metal foil electrodes and plastic films like polyester, polypropylene, polystyrene, or polycarbonate. These materials are wound into a cylindrical shape. Due to their small size, high capacitance, low loss, and excellent high-frequency characteristics, film capacitors are widely used in electronics, home appliances, communications, and power systems.

Application Cases:

Film Capacitors in Inverter Air Conditioners

When the compressor starts, voltage fluctuations can cause partial breakdowns in the capacitor. However, film capacitors can quickly self-heal, ensuring the air conditioner operates steadily and preventing downtime or repair due to capacitor failure.

LED Lighting Driver Circuits

Under external impacts like lightning or power surges, the self-healing properties of film capacitors help prevent full system failure, greatly enhancing the reliability and lifespan of the lighting product.

Unveiling the Self-Healing Mechanism

Self-healing in film capacitors refers to the process where the capacitor restores its insulation properties after a partial dielectric breakdown. When high voltage or external interference causes dielectric breakdown at weak points (like impurities or defects), current flows through a small region, causing a sharp temperature rise. The metal electrodes are very thin, so high temperatures quickly evaporate or melt them. As the temperature of the discharge area drops, the evaporated dielectric material recondenses to form a new insulating layer, effectively isolating the breakdown region and restoring insulation.

Key Factors Influencing Self-Healing Ability

The self-healing ability of film capacitors depends on several factors:

Dielectric Material: It determines the recovery characteristics after breakdown.

Electrode Thickness: Affects the evaporation speed and recovery effectiveness.

Ambient Temperature: Influences the efficiency of the self-healing process.

Manufacturing Process: Determines the overall stability of the capacitor’s structure.

This unique self-healing mechanism allows film capacitors to perform exceptionally well in harsh environments, making them an indispensable component in modern electronic devices.

This article is provided by JYH HSU (JEC) Electronics. JEC is a research, development, production, and sales-oriented company specializing in manufacturing and selling various electronic components such as capacitors and resistors.

Post time: Jul-25-2025